A novel method to avoid the sintering shrinkage of Al2O3-Cr cermets

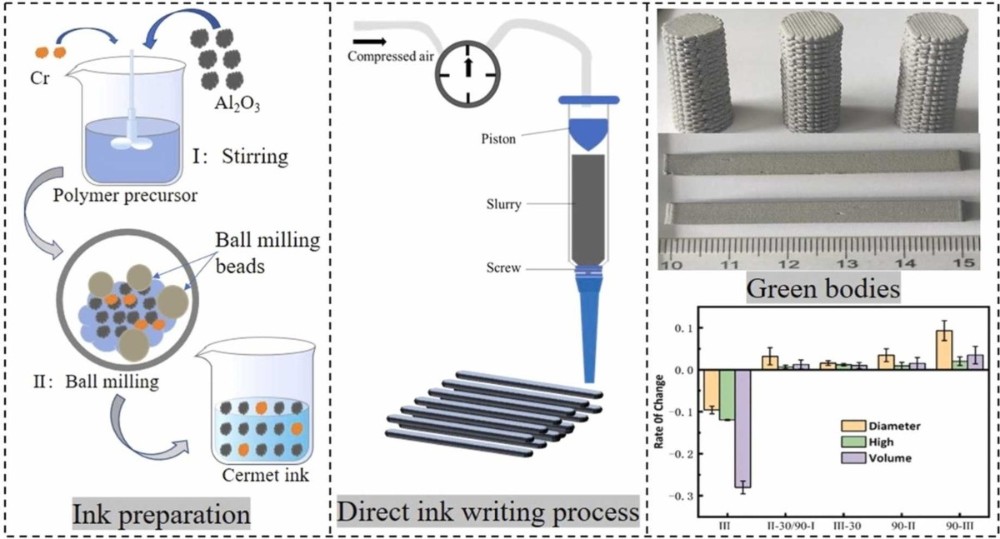

formed by direct ink writing

Diwei Zhang, Chengyi Chu, Siwei Ma, Yuting Wang, Chenqi Duan, Jianjun Guo, Xiaolu Shi, Gaojie Xu, Yuchuan Cheng*, Aihua Sun*

全文链接:Journal of Alloys and Compounds, 2023, 931, 167632

Abstract

The three-dimensional (3D) printed ceramic body often shrinks considerably after thermal processing, which seriously affects the forming accuracy of the final formed parts. In this report, the Al2O3-Cr parts were prepared by 3D direct ink writing. After sintering, the final formed parts have no shrinkage and expanded slightly compared with the green body. Cr plays an important role in this process. The oxidation of Cr causes volume expansion to make up for the sintering shrinkage of the ceramic matrix. The Al2O3-Cr cermet ink exhibits shear-thinning and viscoelastic inversion characteristics, indicating suitability for direct ink writing. A series of printed compacts with different metal and ceramic ratios were sintered at 1600 ℃. The related mechanical properties and microstructure of Al2O3-Cr parts prepared by 3D direct ink writing were investigated. The data of XPS and SEM indicate that Cr reacts with oxygen in the system to produce Cr2O3 during sintering, resulting in the sintered part's volume expansion. This new method provides a good strategy for controlling and eliminating the shrinkage of cermet parts during sintering.